Human Factors Integration

Introduction

The Office for Nuclear Regulation (ONR) Safety Assessment Principles (SAPs) states:

“A nuclear facility is a complex socio-technological system that comprises both engineered and human components. The human contribution to safety can be positive or negative, and may be made during facility design, construction, commissioning, operation, maintenance or decommissioning. A systematic approach to understanding the factors that affect human performance, and minimising the potential for human error to contribute to or escalate faults, therefore needs to be applied throughout the entire facility lifecycle. Assessments of the way in which individual, team and organisational performance can impact upon safety should influence the design of the facility, plant, equipment and administrative controls including emergency arrangements. The allocation of safety actions to human or engineered components should take account of their differing capabilities and limitations. Safety cases need to demonstrate that interactions between human and engineered components are fully understood, and that human actions that might impact on safety are clearly identified and adequately supported.”

The ONR’s expectations with respect to Human Factors Integration (HFI) are set out in the following SAPs, however there are a number of related SAPs (EHF.2 to EHF.12) that must be taken into consideration to ensure human factors are adequately represented in the nuclear safety case:

- EHF.1: A systematic approach to integrating human factors within the design, assessment and management of systems and processes should be applied throughout the facility’s lifecycle.

- MS.2: The organisation should have the capability to secure and maintain the safety of its undertakings.

Whilst HFI is expected throughout all design phases, for new designs the majority of the human factors analysis should be undertaken during the Pre-Construction Safety Report (PCSR) stage in order to influence the design and inform the safety analysis. As the design progresses, human factors analysis should start to focus on verification of the human factors claims in the safety case.

Tailoring the HFI Approach

The exact nature by which HFI is undertaken may vary between duty-holders and projects. This is to be expected although certain key elements (or commensurate activities) should always be evident. Similarly, the level of HFI should be aligned with the size of the project, and take account of the safety reliance on humans and the consequences of human error, together with the novelty and complexity of any new technology. The following HFI SAPs form the key HFI activities that should always be evident on a project:

- EHF.2: Allocation of safety actions (allocation of function).

- EHF.3: Identification of actions impacting safety (Human Error Analysis (HEA) and Human Reliability Analysis (HRA)).

- EHF.4: Identification of administrative controls (HRA).

- EHF.5: Task analysis (Hierarchical Task Analysis (HTA) used as part of HEA and HRA).

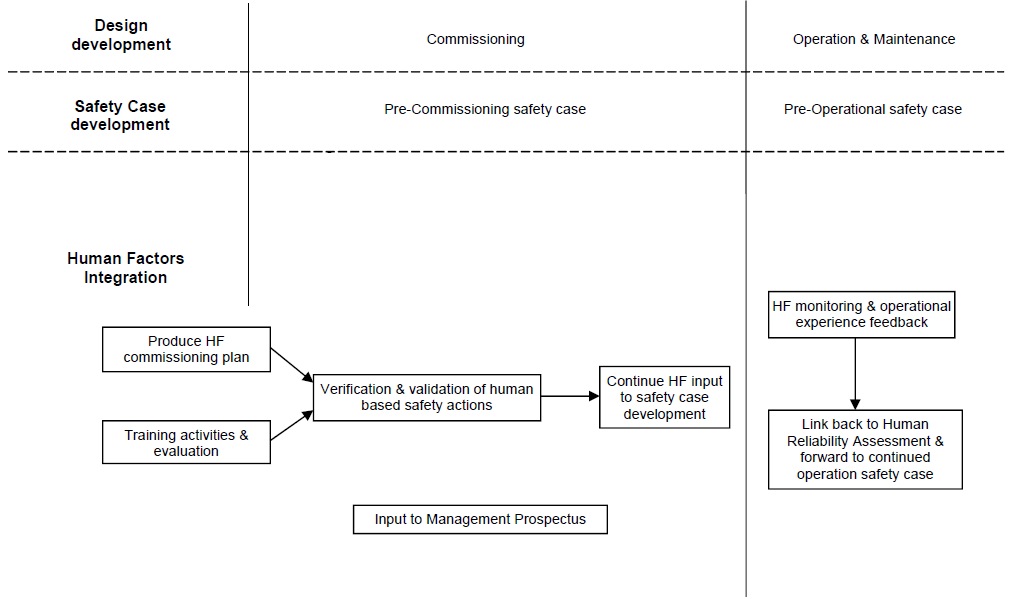

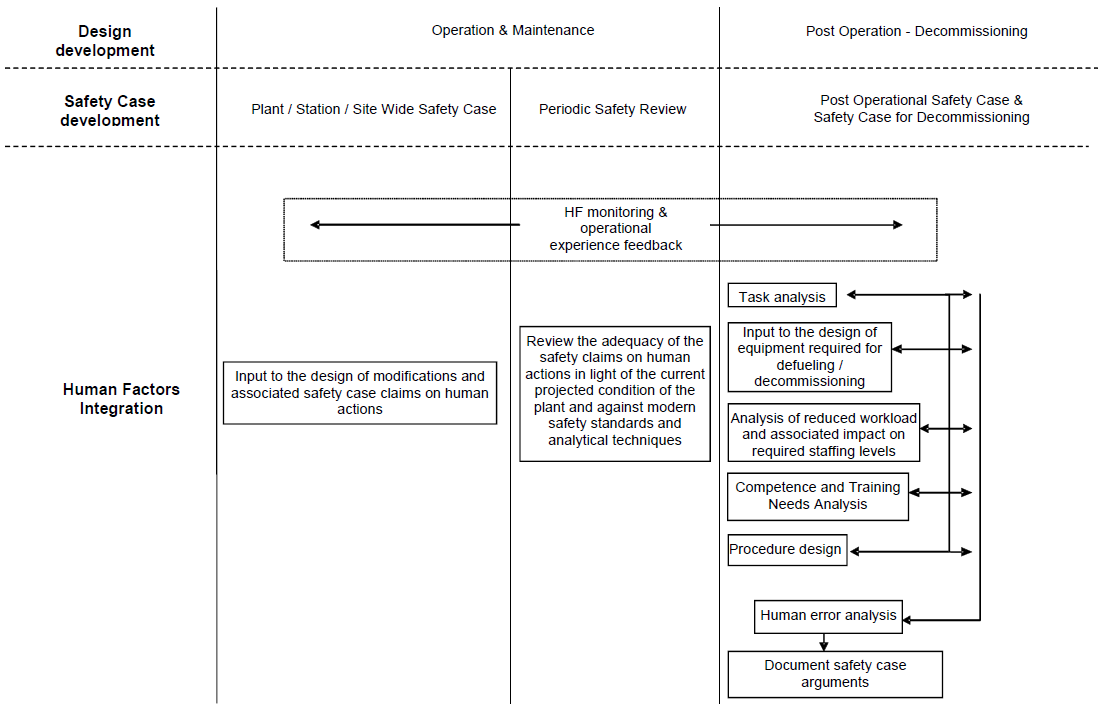

The following diagrams are taken from the ONR Technical Assessment Guide (TAGs) NS-TAST-GD-058 and detail the range of HFI activities which can be conducted over the lifecycle of the safety case.

Further HFI guidance can be found in the International Atomic Energy Agency (IAEA) document SSG-51, Human Factors Engineering in the Design of Nuclear Power Plants.

Additional Information & Guidance

- ONR, Safety Assessment Principles for Nuclear Facilities, 2014 Edition Revision 1 (January 2020).

- ONR, NS-TAST-GD-058, Human Factors Integration, March 2017.

- IAEA, Human Factors Engineering in the Design of Nuclear Power Plants (SSG-51), IAEA: Vienna, 2019.